Eesti teaduse teekaardi objekt NAMUR+

TOF-FIB-SIMS

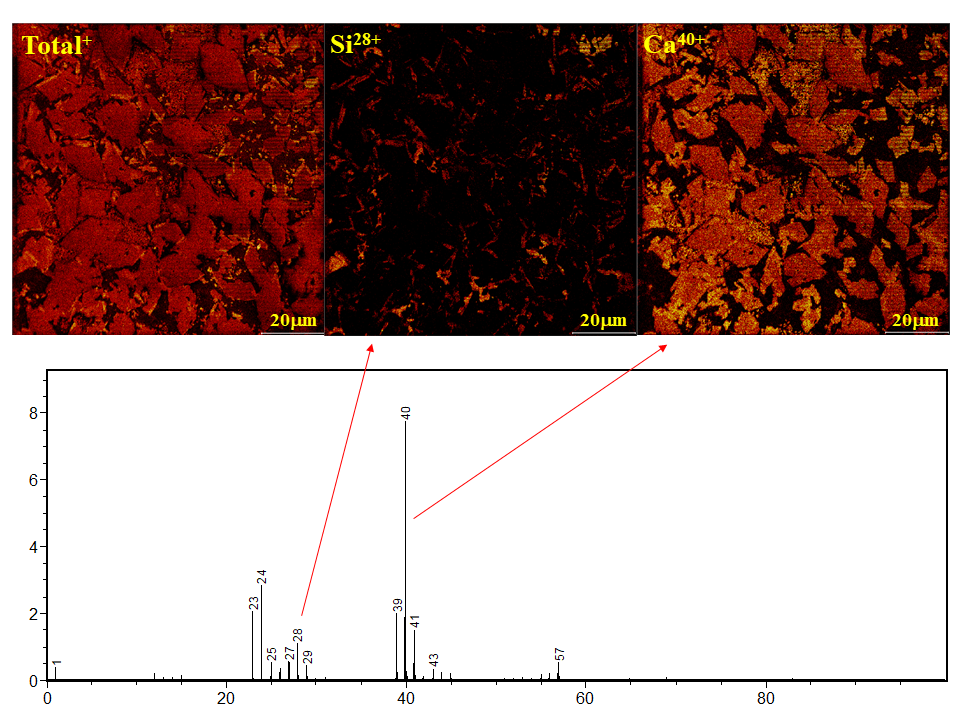

Institute of Chemistry at University of Tartu has the capability to perform elemental analysis of solid surfaces and surface defects using a Physical Electronics nanoTOF II FIB-TOF-SIMS. The FIB-TOF-SIMS is an invaluable tool for quality control and defect analysis due to its very high surface sensitivity which is in the order of a few atomic/molecular layers. In addition, the C60 ion source allows studying defects on thin organic layers and films as well as polymer defects and disorderings.

In addition to atomic layer analysis, the FIB-TOF-SIMS can be used to sputter the surface of the sample using the various ion sources (5kV Ar+, 5kV O-, 30kV C60++) and to construct a depth profile of the sample with sub-nanometer resolution.

In case of macroscopic objects, a depth profile of the chemical composition can be constructed using sequential cutting of the sample using focussed Ga+ ion beam. 200×200 μm cross sections are sequentially analyzed to construct a 3D map of the chemical structure.

It is possible to carry out measurements at different temperatures ranging from −150°C up to 600°C.

Due to the high mass resolution M/ΔM of up to 10,000, the TOF-SIMS can be used to distinguish between the different isotopes of elements, allowing studying of isotope markings of various biological or ionically conductive materials using oxygen-18 or deuterium.

Services include:

- Consultation – scientific and technological aspects will be discussed with a client and evaluated whether a given methodology is suitable for solving client problems;

- Training in the handling of samples;

- The analysis of samples using TOF-SIMS done by experienced operators;

- Help in the analysis of the measurement results and if needed, in interpreting them;

- Development – to work out and implement new methods for solving specific problems using our existing infrastructure;

- Collaboratory research – to solve more complex scientific or technological problems where a few short-term measurements would give inconclusive results.

It is possible to organize training courses for engineers and technicians regarding the different methods of physical characterization of various materials.

Contact person: Enn Lust (e-mail: enn.lust@ut.ee)

Operators: Rait Kanarbik, Priit Möller

Estonian Research Infrastructures Roadmap object „Center of nanomaterials technologies and research (NAMUR+)” is co-fundeded by European Regional Development Fund (projects „Nanomaterials – research and applications“, 3.2.0304.12-0397, 01.02.2012-31.12.2015 and „Center of nanomaterials technologies and research”, 2014-2020.4.01.16-0123, 01.01.2017-30.06.2022). The infrastructure is also supported by the Estonian Research Council (projects TARISTU24-TK26, IUT20-54, and TT13).